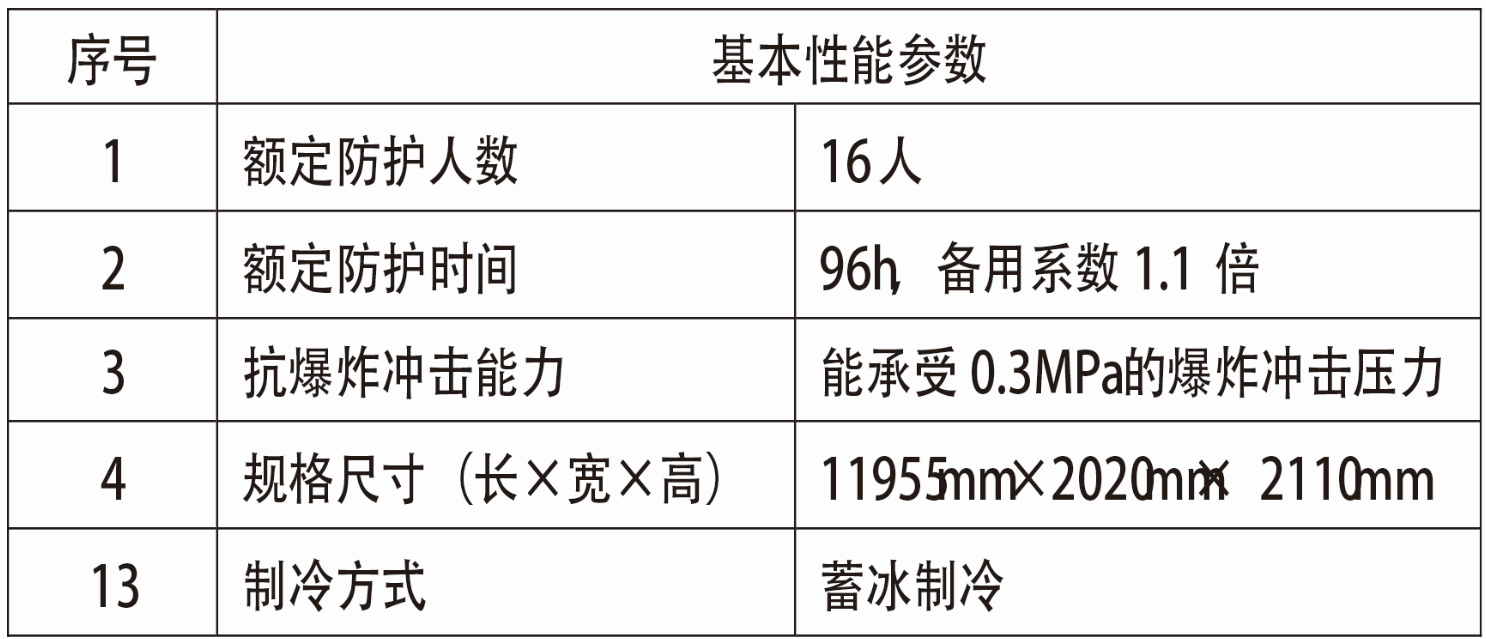

KJF-96/16 Mine Mobile Rescue Cabin

The KYF-96/16 mine movable rescue capsule provides a safe and safe haven space for underground personnel who cannot evacuate when there is a sudden explosion such as an explosion in a coal mine. The rescue capsule can resist external high temperature, explosion shock, roof fall, and insulate toxic and harmful gases; internally, it can provide oxygen, food, water and other necessities for the safe-haven personnel, and treat the toxic and harmful gases, and the safe-keeping personnel are at the rated protection time. Survival needs. The mine mobile rescue capsule officially passed the 106-hour live-action experiment on January 8, 2014.

1. The domestic rescue capsule has the largest volume, and the net storage capacity of 185m3 is the largest rescue capsule of the domestic movable rescue capsule. It can provide a relatively comfortable living space for the evacuation personnel, and has applied for national patents from the shape structure and volume.

2. The structure of the ice storage cabinet is reasonable. It is proved by the real person test that the design is reasonable, and the internal ice cooling capacity can be effectively taken out to dehumidify and cool the cabin, and the effect is remarkable. The ice storage cabinet has applied for national patent.

Hydraulic support

Our company has the qualification of professional overhaul hydraulic support approved by the state, and has a group of professional high-quality talents. Over the years, our company has been carrying out hydraulic support repair for many coal enterprises in Inner Mongolia, Shanxi and Shaanxi. The hydraulic brackets repaired by our company have good performance and high reliability. The main types of brackets for maintenance are shield type, support screen type, top coal type, raft type, water sand filling type and end type.

Roadheader

Our company has the qualifications of professional inspection and excavation machine approved by the state, and has a group of high-quality professional personnel. For many years, we have been repairing roadheaders for many coal enterprises in Inner Mongolia, Shanxi and Shaanxi. The hydraulic support that our company overhauls has good performance and high reliability.

Introduction to the dumping platform

First, use:

Our company is specialized in the development and production of full-hydraulic rear reclining and roll-type quick unloading machines. The product is suitable for rapid unloading of bulk materials in electric power, chemical, chemical, grain, cement, coal and other industries. It completely solves the safety problems of vehicle equipment and personnel during the unloading process, and at the same time improves the speed of unloading, reduces the pollution of workers and air during unloading, and reduces the cost of unloading.

The unloading platform produced by our company is widely used in water mixing, food, electric power, metallurgy and other industries, improving the efficiency by dozens of times, saving millions of dollars in the following year. Through the unremitting efforts of all employees of the company, the product has been sold well in Neijiagu, Ningxia, Sichuan and other regions, and the equipment operation rate is 100%, which is very popular among users.

At present, our company can design and produce various specifications of products according to the different needs of users. At the same time, in order to meet the needs of users, our company has also developed supporting dust removal equipment, which realizes zero loss of materials during unloading and zero pollution of unloading environment.

Second, the dumping work process and product features:

When the heavy-duty truck with bulk materials is positioned in the middle of the platform, the operator operates the electric control button in the control room (the dynamic situation of the unloading platform and the vehicle can be seen from the control room), and the hydraulic cylinder is slowly synchronized. When it stops at a certain position, when all the materials are discharged, the electronic control button platform is operated from the control room to return to the platform steady state (when the cylinder is restored without stroke), the freight car is driven off the platform.

This product has the following main features: 1. The unloading tonnage is large. 2. Short unloading time and high production efficiency. 3. The input power is small and the running cost is low. 4, the whole process can be manual / automatic operation, automatic unloading can achieve 1 button unloading, 1 button reset, easy to operate. 5. The equipment structure is scientific and reasonable, reliable in operation and easy to maintain and repair. 6. The side (rear) dump truck platform has added an automatic locking brake wheel device. When the semi-trailer is tilted and unloaded, the pressure wheel device automatically presses the wheel on the other side of the tilting direction of the semi-trailer, thereby making the semi-trailer a large angle. The semi-trailer does not fall to the chute on the outside of the platform when the material is unloaded, which improves the safety performance. At present, our company has applied for national patents for the pressure-reducing wheel device. 7. A large number of unloading costs are saved, and the investment recovery period is short.

Third, product protection and services:

For each factory product, our company has set up the product number, establish product files, track services, and timely understand and solve the equipment operation status and problems reflected by users. The perfect after-sales service system allows users to use with confidence .

Fourth, the specification model

CPS mine grooved pipe fittings

Our company produces CPS pipe joints of various specifications and models, including CPS rigid pipe clamp, CPS reducer pipe clamp, CPS conversion flange, CPS elbow, CPS tee/four-way, CPS reducer tee/four-way, etc. Etc., complete product specifications, quality assurance. Widely used in construction, industrial and mining, petroleum, chemical, electric power, marine and water treatment engineering industries. The product meets the US UL213 standard, and the company is also the first to obtain S09001-2000 certification.

According to the needs of customers, our company can send technicians to carry out on-site guidance installation and debugging. For the problems that arise during the future use, the company’s after-sales service personnel will rush to the scene to solve the problem.